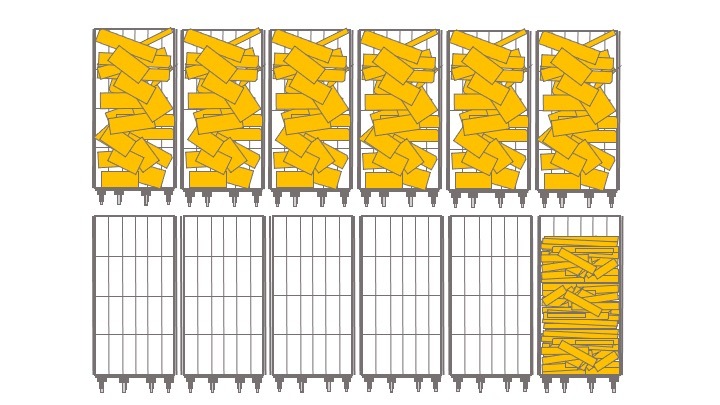

Cage to Card The Roll Cage compacted in the SpaceMate and removed to be refilled and placed back into the machine the until full. The natural expansion of the card limits this method to a 4:1 ratio. Once full, the ejected cage can be wrapped, closed or fitted with a cage front ready to be transported.

SpaceMate is a hydraulic compacting machine designed to maximise the amount of waste product in a rolling goods cage without damaging the cage itself.

SpaceMate compacts card or plastic whilst it's in the cage reducing handling and the recycling volume by 75% and at the same time reducing cage requirements by the same amount. The hidden benefits are impressive too: Store congestion is reduced as other return items such as pallets and trays can be returned or more loads collected on the back haul.

Card to Cage The Roll Cage is left inside the SpaceMate for the duration until full. For each compaction the card is fed in through the top door, then closed for compaction. This allows the natural expansion of the card to be contained inside the machine until it is released when full. Once ejected the cage can then be wrapped, closed or fitted with a cage front ready to be transported for 6:1 compress.

SpaceMate is a hydraulic compacting machine designed to maximise the amount of waste product in a rolling goods cage without damaging the cage itself.

SpaceMate compacts card or plastic whilst it's in the cage reducing handling and the recycling volume by 83% and at the same time reducing cage requirements by the same amount. Plastic wrap savings of 83%. The hidden benefits are impressive too: Store congestion is reduced as other return items such as pallets and trays can be returned or more loads collected on the back haul.

The modern supermarket landscape is evolving, with a growing emphasis on sustainability, operational efficiency, and cost savings. In this context, the SpaceMate In-Roll Cage Cardboard Compactor emerges as a game-changer. This is why supermarkets are wholeheartedly embrace the SpaceMate for labour savings, enhanced roll cage availability, and a significant reduction in their carbon footprint.

1. Labour Savings:

In the hectic environment of a supermarket, every moment counts. Traditional waste disposal methods often involve time-consuming and labour-intensive tasks, like manually breaking down cardboard boxes. The SpaceMate Roll Cage Cardboard Compactor eliminates this need. Employees can effortlessly place cardboard directly into the SpaceMate, where it gets efficiently compressed. This process not only saves valuable employee time but also reduces the risk of workplaceRSI associated with manual cardboard handling.

2. Availability of Roll Cages:

One of the critical aspects of supermarket logistics is ensuring an adequate supply of roll cages. These mobile storage units are vital for transporting goods throughout the supply chain. However, they often get trapped in the system, filled with empty cardboard boxes waiting for disposal. The SpaceMate eliminates this bottleneck by compacting cardboard waste within roll cages, ensuring they are readily available for their primary purpose - moving products. Supermarkets can maintain a seamless flow of goods without disruptions, leading to a more organised and efficient store environment with improved roll cage availability from 75-83% depending on operational requirements.

3. Carbon Footprint Reduction:

Sustainability is no longer an option; it's an imperative for businesses today. Supermarkets generate substantial cardboard waste, but with the SpaceMate, they can make a substantial impact on their carbon footprint. By compacting cardboard at the source, supermarkets reduce the volume of waste sent to their recycling facilities. This translates into fewer waste collections, lower transportation emissions, and decreased labour cost during the recycling processes. Ultimately, the SpaceMaker contributes to a significant reduction in the supermarket's overall carbon footprint.

4. Cost Savings:

Labour, waste management, and roll cage procurement are significant cost factors for supermarkets. The SpaceMate In-Roll Cage Cardboard Compactor addresses all these areas, leading to substantial cost savings. Fewer labour hours spent on manual cardboard handling mean reduced payroll hours and fewer workplace injuries. Additionally, supermarkets can save on waste management processing fees and the purchase of additional roll cages, which can be a significant investment. These cost savings directly impact the supermarket's profitability and bottom line.

Conclusion:

The SpaceMate Roll Cage Cardboard Compactor is a transformative solution that addresses multiple challenges faced by modern supermarkets. From labour savings and enhanced roll cage availability to a commendable reduction in the carbon footprint, this technology offers a holistic approach to improving supermarket operations. By embracing the SpaceMate, supermarkets position themselves as forward-thinking, environmentally responsible businesses that prioritise efficiency and sustainability. This innovative solution not only benefits the bottom line but also contributes to a greener future.